Retail merchants now track at the SKU level, digital mapping relies on GPS coordinates, and Major League Baseball measures the velocity, position and spin rate of every pitch. These industries, among others, have maximized the use of accurate data to increase productivity, minimize risk and strategically and proactively forecast business outcomes. In large part, they’ve done so by creating and gathering data that lies at the core of their businesses.

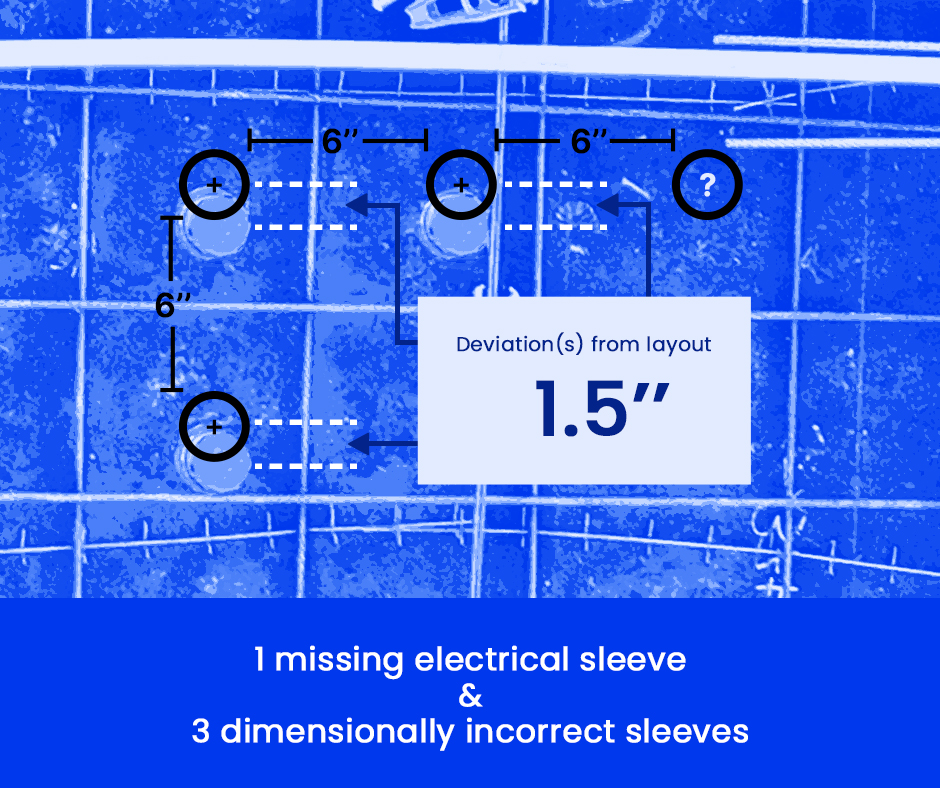

The construction industry’s equivalent of the SKU, GPS coordinate or pitch is a new term identified as individual “element-level” data. On the jobsite, this translates to everything from a plumbing sleeve and PT tendons to façade panels, embeds and all of the materials required to create an integrated system. Element-level data is gathered via digital construction verification (DCV), which leverages technology to identify and categorize each individual element to systematically verify and report that each element is installed correctly in the field, during—not after—installation. Until the advent of DCV, these insights remained hidden on the jobsite.

Why Element-Level Data Matters

At its core, element-level data and element-level reports unlock the ability to derive a variety of insights based on the quantity and variety of data that is systematically collected prior to, during and after installation of elements on jobsites. A wealth of insights can be gained from seemingly basic factors inherent to each element—for example, element type, trade, quality, quantity, dimension, direction, location, install time, install accuracy and dependencies—and the relationships between them.

Element-level, data-driven reports fuel a powerful understanding of fieldwork performance. When delivered promptly, these performance insights enable field teams to quickly correct errors at the source and help predict where future issues may arise. When delivered to the right project participants, they empower teams to self-correct and have a profound impact on individual project productivity as well as overall strategic business planning and actions.

When delivered within context, they allow owners, developers, investors and GCs to assess overall project and business performance, which unlocks the ability to not only assess current fieldwork but also make data-driven decisions about the business. For example, insight into which trades tend to perform better (both relatively and absolutely) allows superintendents to focus on specific trades or circumstances. Similarly, an understanding of the performance of a specific product type (e.g., office, residential or healthcare) or subcontractor (e.g., MEP, concrete or façade) helps inform the choice of project teams or trade partners for the next project.

Historically, fieldwork performance has been a lagging indicator characterized by non-standard measurements and a heavy reliance on instincts and personal experience. By standardizing element-level performance as a set of metrics, in this case real-time measured outcomes, performance can be added to the experience equation and applied to any construction project. Element-level reports driven by data turn fieldwork performance into a leading indicator by enabling a data-based score that removes emotion and is less likely to be misinterpreted.

How DCV Unlocks Element-Level Data

Image capture is just the starting point for DCV, which ultimately provides insights into the accuracy of installation of each individual element. DCV tags every element in CAD, BIM and shop drawings and then verifies that they are installed in line with the project’s defined tolerances and standards. It breaks down silos of information between project participants to create a common, measurable standard for construction for quality, performance, schedule, speed, conformance and engagement in fixing errors.

The Metrics Element-Level Data Enables

Just as the FICO scoring system many financial institutions use when evaluating whether to grant a loan encompasses multiple components—including repayment history, types of loans, length of credit history and an individual’s total debt—the performance score for fieldwork accounts for multiple factors. Based on an analysis of data from more than $10 billion in U.S. commercial construction projects, SiteAware has created a scoring system for fieldwork that takes into account three key metrics driving the success of a construction project: mitigation, installation progress and trade accuracy. This performance score allows for a normalized view in which the performance of a single trade or project can be measured over time and compared against benchmarks and peers.

- Mitigation A measure of risk mitigation that reflects the percentage of observations that have been treated.

- Installation progress The percentage of elements in the plans that have been installed, indicating the amount of work in progress (WIP) remaining in the last shift prior to a pour.

- Trade accuracy The percentage of elements initially installed within defined project tolerances (referred to as First-Time Quality in many industries).

Picture the Performance that Emerges from the Data

Consider what you could do with element-level data that covers each trade on the jobsite. For example, data reveals that the industry overall has a performance score of 86.82%, which shows that concrete pours begin with 13% of the elements at risk. Two-thirds of that risk, nearly 9% of all planned elements, consists of elements not yet installed at the beginning of the shift when concrete is being poured.

Using the performance rating, we found that exposure to risk varies among the type of project: 17.5% of elements on commercial jobsites are exposed to risk, compared to 11.3% for multifamily and 26.4% on low-rise residential.

What does this mean for the industry? Performance metrics that can be applied to any construction project create a standard that businesses can measure, track and enforce across trades, clients and project portfolios.

That’s just the beginning. Learn more about the power of element-level data in our report, “A New Foundation for Construction Data.”